enamel glaze Options

enamel glaze Options

Blog Article

This method results in tender, translucent layers of colour that blend and stream, evoking a watercolor-like impact on your ceramics. Experiment with layering and Mixing various colours to accomplish An array of captivating and dreamy effects.

Strip The Old Enamel: The first step is to get rid of the outdated enamel with the cookware’s surface. There are two prevalent techniques for this: utilizing a chemical paint stripper or utilizing a sandblasting course of action. Both techniques demand caution to prevent harmful the cookware’s base materials.

Glazing requires coating the pottery with a glaze mixture then firing it inside a kiln, the place the glaze melts and sorts a glassy surface.

Enamel, On the flip side, entails fusing powdered glass to your substrate by firing, generally among 750 and 850°C, developing a colorful, shiny surface area that may be really hard and immune to corrosion.

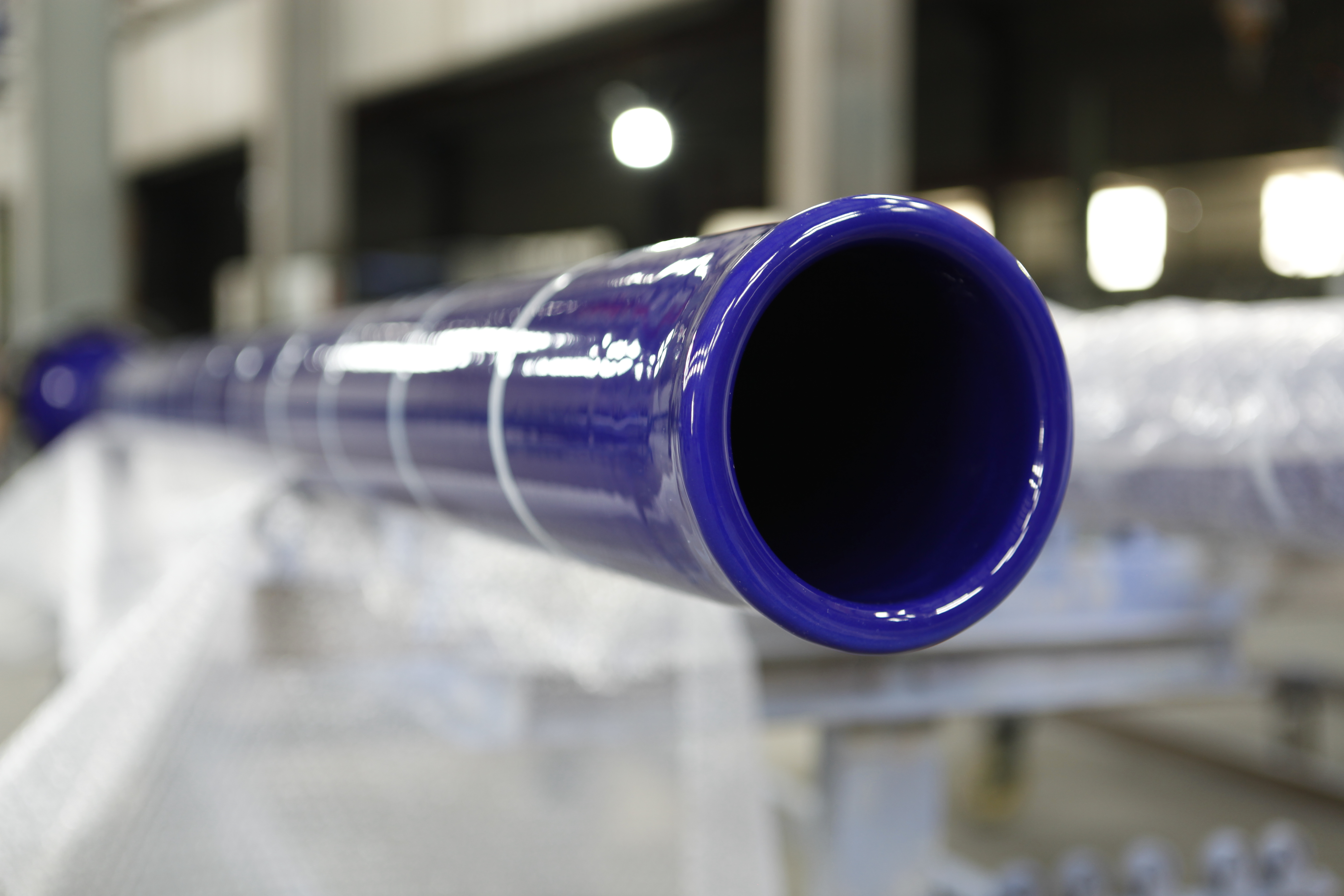

In view of your defects from the prior artwork, the creation aims to supply a glass-lined glaze, an anti-corrosion layer within an oil subject pipeline as well as a preparation system thereof, which can be used for resolving the problems which the sintering temperature of the glass-lined glaze is too high, the anti-corrosion layer inside the glass glaze with the oil discipline pipeline has weak acid resistance, corrosion resistance and effects resistance, the adhesion using a matrix is weak plus the like while in the prior art.

(3) and (three) putting the glass-lined glaze product geared up during the move (2) right into a spraying device for looking forward to spraying, derusting the oil field pipeline, preheating for 1h at four hundred ℃ spraying the glass-lined glaze materials on the internal surface with the oil discipline pipeline under the action of inert compressed gas uniformly, And eventually, enameling and burning to prepare an interior anticorrosive layer from the oil industry pipeline, wherein the enameling and burning temperature is 750 ℃ and the enameling and burning time is two hours.

Greater than 10 years of user feedback has proved that the standard is very special enamel glazes ideal, enamel problems in the chance of even significantly a lot less than the superb companies abroad.

Ceramics are made by shaping clay into preferred forms after which you can firing them at significant temperatures in a very kiln to harden them.

Gentle Scrubbing: Gently scrub the rust places utilizing the baking soda paste. The delicate abrasive Attributes of baking soda can help raise the rust without having resulting in harm to the enamel.

Abilities And Experience: Trustworthy organizations that specialize in re-enameling have the required knowledge and knowledge to deal with the restoration method with precision. Their competent specialists are accustomed to the intricacies of enamel application and curing, ensuring a high-quality result.

Steer clear of Tough Water: For those who have tough water, think about using filtered h2o for cooking and cleansing to avoid mineral deposits about the enamel.

Picking to reglaze your bathtub is not a call you must make within the fly. Before committing to this hefty Do-it-yourself, It is a smart idea to weigh your choices With regards to the two refinishing your tub and

Enamel is common in jewelry producing for its power to offer lively shades and a sturdy, shiny end that boosts the beauty and longevity of pieces.

Repairing insignificant chips from the enamel may help keep the cookware’s aesthetics and prevent the chips from developing into larger sized difficulties. Even though enamel fix kits are efficient for insignificant chips, Take into account that they will not be well suited for much more important enamel hurt.